3.1 Production cycle optimization in a robot-cell

In general the Production Cycle is a time period during which inventories are being turned by the company into finished good.

For the company the decrease of the production cycle is desirable. Such dynamics means that the company is decreasing the amount of time needed for turning its average inventories into finished goods. Short operation cycle allows to decrease the share of fixed expenses in each dollar of manufactured goods and provided services. The production cycle is different for different industries and business segments. For example, the production cycle for the windows manufacturing enterprise would be much shorter, than for the automobile manufacturers. For more precise estimation of the company’s financial condition it is reasonable to compare the company’s production cycle with main competitors.

Production cycle for the whole company is characterized by the total throughput time.

TT - machining time (töötlemisaeg)

m - number of manufacturing positions in production route (töötlemispositsioonide arv toote valmistamisel)

TK - assembly time (koostamisaeg)

k - number of needed positions for assembly fin the production route (erinevate koostamise töökohtade arv toote valmistamisel)

TM - time for measurements, check time (mõõtmise ja kontrolliaeg)

l - number of check positions (erinevate mõõtmisoperatsioonide arv)

TP - time for set-up (paigaldusteks/seadistustusteks kuluv aeg)

ρ - number of set-up operations in the production process (paigaldus-seadistusoperatsioonide arv)

TR - time for inbound logistics (transpordiaeg)

n - transpordioperatsioonide arv

TO - idle time (summaarne ooteaeg)

Manufacturing process is a logical sequence of production operations. Production operation is connected with a workplace (Cell). Here we consider on the Cell level.

Cycle time for the production operation – is the period required to complete one operation, or to complete a function, job, or task from started to finish in a certain workplace.

As production tasks are different, different are also the workplaces for fulfilling these tasks, the components of cycle time are depending directly from the character of the duty the workplace is needed to do.

A cycle time analysis is any method that collects and analyzes time data for a process to improve the total process or system. Cycle time determines the robot production rate for the job. The production rate depends a lot from the workplace management. Prerequisites for effective work are created by choosing the right equipment and designing the layout. Cycle time is in tight correlation with the production cycle organisation in the workplace.

A production cycle example for machine tending is given below:

- Cycle starts with arm located at position 1

- Robot picks up part

- Then moves to position 2

- Loads part into machine

- Returns to position 2 and waits

- Moves into machine and gets part

- Moves to output conveyor and releases part

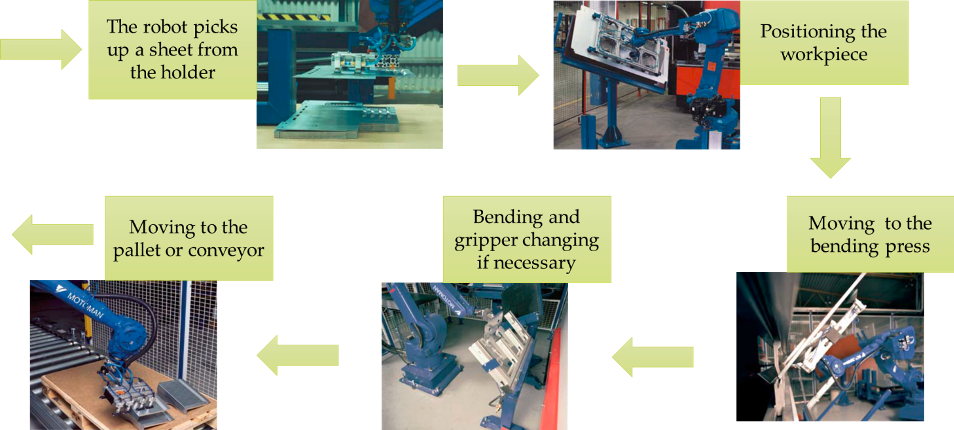

3.2 Bending cycle description

- Feeding

The entire stock of sheets to be processed is manually or automatically (with the mobile robot, etc) placed on the feeding table (holder or raw materials buffer). A sheet detection switch is installed on the feeding table to prevent the robot from grabbing the tray.

- Reclamping

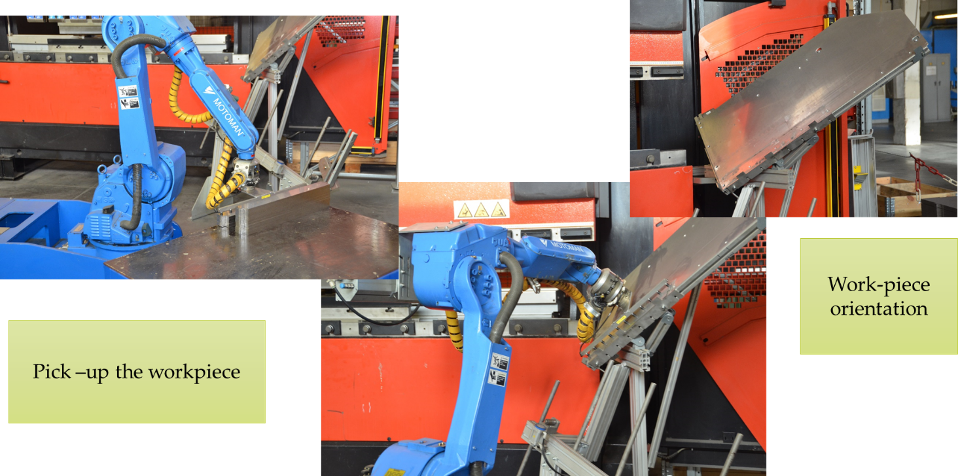

The robot moves to the position of the loading table and detects the height of the plate by an ultrasonic sensor installed on the gripper. According to the detection data, it will automatically run to the appropriate position to grab the sheet. After the sheet is grapped the thickness of the sheet is measured by the thickness measurement device.

- Alignment

The robot runs to the position of the positioning table and places the sheet on the positioning table for precise positioning. After positioning, grab the sheet again and prepare for bending.

- Bending

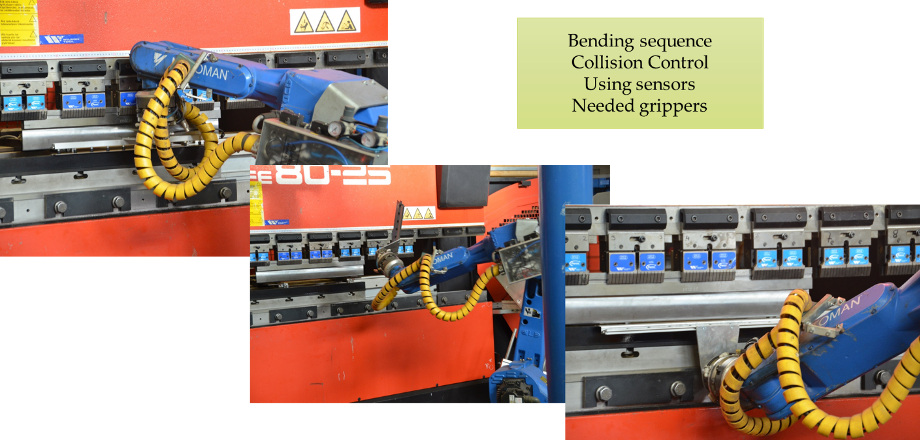

The robot moves to the position of the press brake machine, places the sheet flat on the lower die, and accurately positions it by means of the rear finger sensor of the press brake machine. After the positioning is completed, the robot sends a bending signal to the press brake machine and cooperates with the bending machine to complete the bending action.

The technical difficulty of the bending lies in the cooperative action of the robot and bending machine, that is bending following. When the robot grips or supports the sheet during bending, the sheet is deformed. The robot needs to follow the sheet to make a circular motion according to the specific trajectory algorithm, and always maintain a relatively fixedposition with the sheet.

- OFF-LINE AND ON-LINE PROGRAMMING OF IR

- The teaching materials are presented separately

- Palletizing

The robot runs to the position of the unloading table (buffer of finished goods). Due to the difference of the forming of the workpiece there are variety of palletizing actions. Such as conventional matrix palletizing, single and double layer cross palletizing and negative buckle palletizing, etc.

3.3 Bending cycle optimization

Optimization means the best possible solution to a problem given a constraint set, which is also called the feasible set. Here, we do not solve a typical optimization problem with a goal function and constraint conditions (they may also not exist). The goal function in production is typically to ensure maximum productivity or minimum production cost. In this section, we will focus a little on issues that are directly related to the efficiency of the bending process.

We have previously stated that the bending cycle is performed at the workplace and largely depends on the equipment used in the workplace and their layout scheme. The time of the bending cycle (production cycle) depends directly on the technological capabilities of the robot and the travelled length covered by the industrial robot.

Tasks T2

-

-

- Design a robot-bending cell for a given part. Justify the choice of equipment. Justify the layout (location of equipment.)

- Design the movements of a robot. Working cycle. Determine approximately the time for the cycle.

- Analysis of the effects of cycle time on productivity, quality, process flexibility.

- What are the criteria to flexibility and how these are in correlation with the manufacturing task and robot-cell functionality

-

Questions Q3

-

-

- What are the main components of a bending press, what is their function and how do the technological possibilities of the device develop?

- Describe the job of robot bending. What determines the layout of the equipment used

- How the choice of a robot in a painting workplace is related to the functionality of an existing bending press

- Under what circumstances is it expedient to automate the bending operation in the company

- What is the purpose of using sensors in a bending operation and what is the role of the gripper system. Whether they can be related to each other or whether it is expedient to use them separately

-

Qestions Q4

-

-

- What are the main components of a bending press, what is their function and how would be formed the technological possibilities of the device ?

- Describe the robot bending workplace. What determines the layout of the robot-bending workplace (robot-bending cell)

- How the choice of a robot in a robot-bending workplace is related to the functionality of an existing bending press

- Under what circumstances is it expedient to automate the bending operation in the company

- What is the purpose of using sensors in a bending operation and what is the role of the gripper system. Whether they can be related to each other or whether it is expedient to use them separately

-

Workflow in the bending cell