Problem description1

Production automation and digitalization is a definite trend in business today. At the same time, production technologies and the equipment that supports them are becoming increasingly complex. The goal is to produce various products in small batches, with high productivity, high quality and as efficiently as possible. Different processing methods are used in production. Sheet metal processing is a widespread field in mechanical engineering. Bending, in turn, is a very widely used processing method in mechanical engineering. Robot bending is widely used to automate the process. This training material looks at what a robotic workplace looks like today, how bending technology is developed and what you need to know to effectively make different products in a robot-cell. The complex engineering task is decomposed into narrower parts and here it is solved in integrated stages and it is indicated in which position the employee is responsible for solving the given tasks in the company and how there tasks are related to the study programme.

Roles2

There are three levels of engineering tasks considered with the workplace (robot-based bending cell) for manufacturing the needed parts.

- Macro planning – Deals with higher level planning of integrated manufacturing: selection of robots, bending equipment, workplace layout design, part families composition, order management, tooling solutions, etc. These are the high level of engineering activities and systems engineers(production engineers) are usually the staff for deciding the problems (see needed competences of system engineers).

- Micro planners deal with the operating level decisions, such as designing the operation technology, organising the tooling, maintenance of equipment, off-line programming, statistical process control, handling the program library. The robot-based workplaces must be ready for manufacturing and fulfilling the planned orders.- Robot system technicians are the staff at this position and the competence chard explains the needed competences

- Operation executers are dealing with fulfilling the production task. For this purpose is needed to put in order the workplace, if necessary to select the operation parameters, if necessary to generate the NC codes, to operate the bending machine and industrial robot, to follow the rules for achieving the needed quality and quantity of products. Robot operators are the right persons for operating in the robot-based workplace and producing the goods. Needed competences are described in the robot-operator competence chards.

Link to the competence chards.

- Output and objective description3

The main output is having knowledge about bending task execution in the robot-bending cell. This means how the manufacturing task is integrated with the bending technology and bending workplace inside a production system.

The main competences obtained are:

- Knowledge about robot-bending cell

- Knowledge about bending technology

- Skills about organizing the bending cycle

- Skills about bending workplace organisation

1 Please describe the problem based on the previously listed use case topics. The problem should have a direct connection to the industry and should be strictly defined.

2 Please link roles relating to the problem defined previously to competence chart’s or industry professions.

3 Please describe the output which solving the problem produces. Also describe the objective of the use case from the student point of view.

4 Please describe main steps for solution including the hierarchy of the task like process steps or phases.

5 Please describe the process how the solution is achieved. What are the steps which will lead to the solution. Please also describe methodology/rules/boundries/conditions/guidelines for the task solving process if these are given to students.

6 Please define more detailed and spesific instrcuctions/methods/tools for solving the process if these are given to students.

7 Please define how the results are interpretatined and assessed.

8 Please propose a smart e-learning tools/methods/material to implement the use case for work-based education.

9 Please propose an ideas/visions/concrete solutions/tools/experiments how implement AI in smart e-learning.

Robot Bending

Robot Bending is an important part of sheet metal products processing Objective of the use-case is to describe the robot-bending process with the needed technology and equipment in a robot-bending cell (workplace).

Workplace is a single unit of a production system that is organized on the basis of machine tool (or group of machine tools) serviced by an robot (operator) and additional servicing equipment if needed. Workplaces are integrated into the production system. This production system belongs to a company, which could be a part of an industrial network or cluster. The workplace integration with systems and processes could happen through the material flows and information flows.

Robotization task formulation. The following parameters are important for understanding about the production task

-

-

- Product (parametrical description)

- Nomenclature (product families)

- Amount of production (per year, per month)

- Production process

- Business model

- Integration

-

Starting with the bending operation

Questions Q1

-

-

- How the production task parametrical numbers influence to the workplace structure and its integration to the production system

- Give examples of bended workpieces. For what purpose these are used

- How to describe a real task for bending for a company

- What type of machine tools are needed for bending workplace

- What are the raw materials for bending operations

-

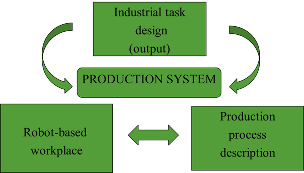

There are three main components of the bending process for producing needed parts (according to the industrial task):

- Robot based workplace for the bending operations

- Industrial task – workpieces drawings with the technical parameters for bending (CAD model) and needed amount of production (batch sizes, batch replicates)

- Production process description (process technology, operation technology)

All these parts are integrated through a production system.

- Task decompositio4

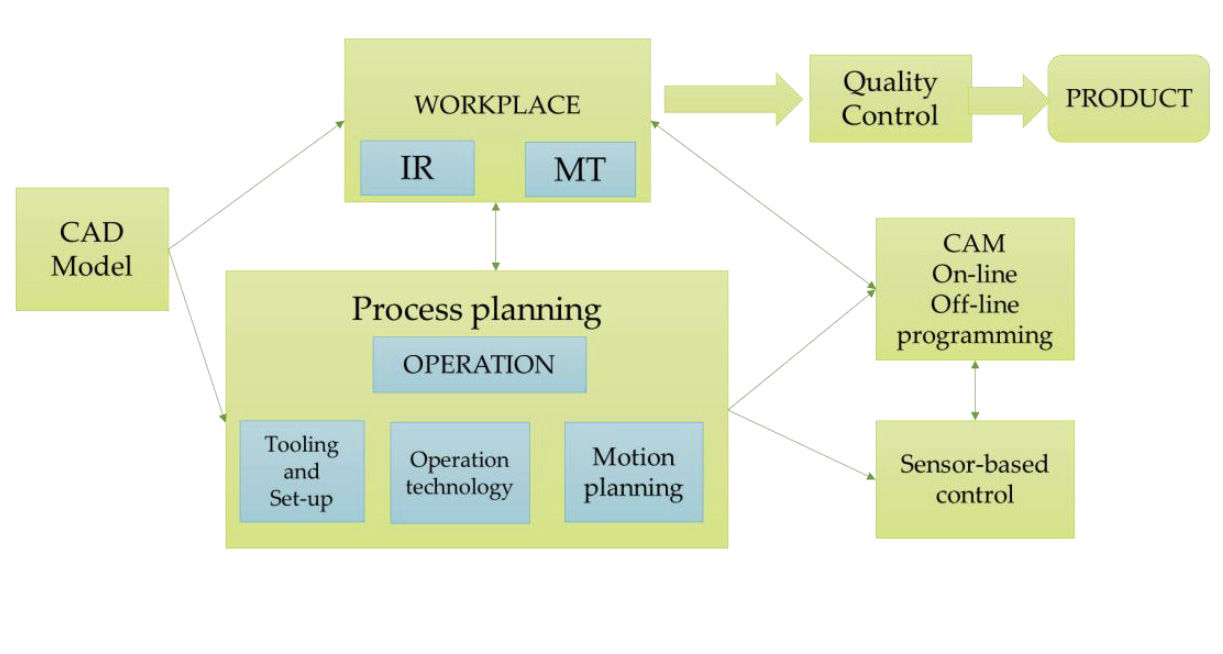

The task is to solve the problem of manufacturing the given workpieces in the robot-based bending cell. This is a complex manufacturing task which have several subtasks. So the whole problem is possible to divide to several subproblems, which all have a great role to quality of product, to the efficiency and productivity of production. The studying task content is given in the following picture.

| IR – Industrial robot | MT – machine tool (Bending press) |

- Task solving process5