Problem description

At the present time there is a very large number of different industrial robots what are offered by the robot manufactures. The nomenclature of these is increasing constantly. For understanding about the industrial robots, the suitability and possibilities of using the industrial robots in the industry, it is necessary to have a knowledge about these selection principles and effective utilization in the robot-cells (robot-based workplaces).

Roles

There are three levels of engineering tasks considered with the workplace (robot-based bending cell) for manufacturing the needed parts.

-

- Macro planning – Deals with higher level planning of integrated manufacturing: selection of industrial robots, different equipment, workplace layout design, part families composition, order management, end-of-tooling solutions, etc. In this area these is a high level of engineering activities and different professionals like systems engineers (production engineers), mechatronics, robot systems technicians are usually the staff for deciding the above-mentioned problems (see needed competences of system engineers).

- Micro planners deal with the operating level decisions, such as designing the operation technology, organising the tooling, maintenance of equipment, off-line programming, statistical process control, handling the program library. The robot-based workplaces must be ready for manufacturing and fulfilling the planned tasks.. Robot system technicians are the staff at this position and the competence chard explains the needed competences

- Operation executers are dealing with fulfilling the production task. For this purpose is needed to put in order the workplace, if necessary to select the operation parameters, if necessary to generate the NC codes, to operate the bending machine and industrial robot, to follow the rules for achieving the needed quality and quantity of products. Robot operators are the right persons for operating in the robot-based workplace and producing the goods. Needed competences are described in the robot-operator competence chards.

Link to the competence chards.

Output and objective description3

This use-case is as a practical example how integrated are the nowadays industrial topics and how much practical support is necessary for solving them. The developed examples are very tightly connected with the every-day problems in the companies.

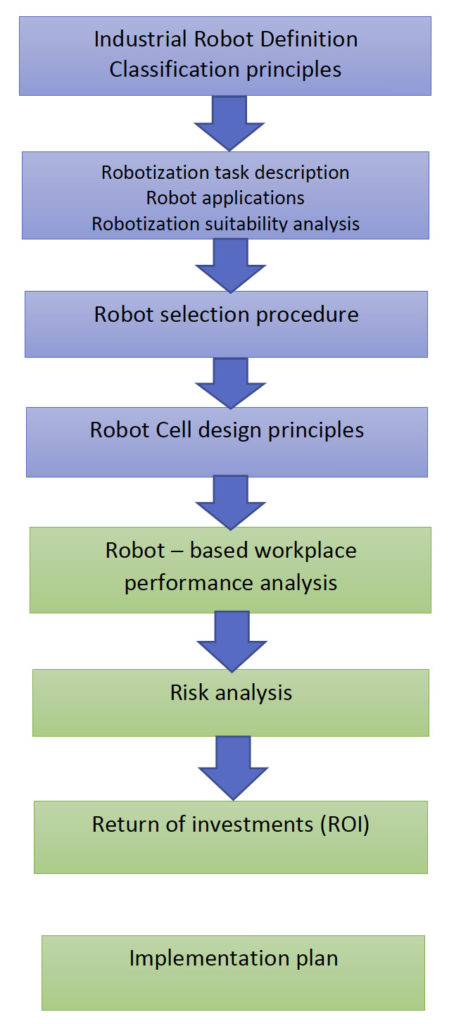

The primary objective of this use-case is to describe and analyse the different situations of using industrial robots in the companies, to give knowledge about the decision making procedures for robot selection ang designing the most suitable robot-cell, but also to give practical advice of achieving the expected performance by implementing the robot-based workplace.

There in necessary to describe the selection of decision-making criteria from different aspects (easy to understand, having significant influence, giving the value of suitability, etc) and using these in different situations (company view, producers view, competence centre view) in the decision making process.

To understand what is the best case for robotization is an important task for manufactures as the productivity of a workplace and efficiency of a production system has a direct correlation to the quality of decision. The robot selection is a multicriterial and multidimensional task. There is not enough to have a good classification system for robots or to have a simulation system for robot cells. It is necessary to go more deeply to the decision-making process, to understand the features for optimal robot selection.

Knowledge and skills obtained

-

- Understanding about industrial robots

- Understanding about integrated manufacturing

- Knowledge about industrial robot applications

- Knowledge of using industrial robots in the companies

- Skills for industrial robot selection

- Skills for design the robot-cell

- Knowledge about robot-cell applications

- Understanding about performance of a work-place

- Skills for determining the needed KPI`s and using the data and information for improving the performance

- Skills for risk analysis

- Skills for calculation important efficiency parameters (OEE, DEEP, etc)

- Skills for calculation ROI

Task decomposition

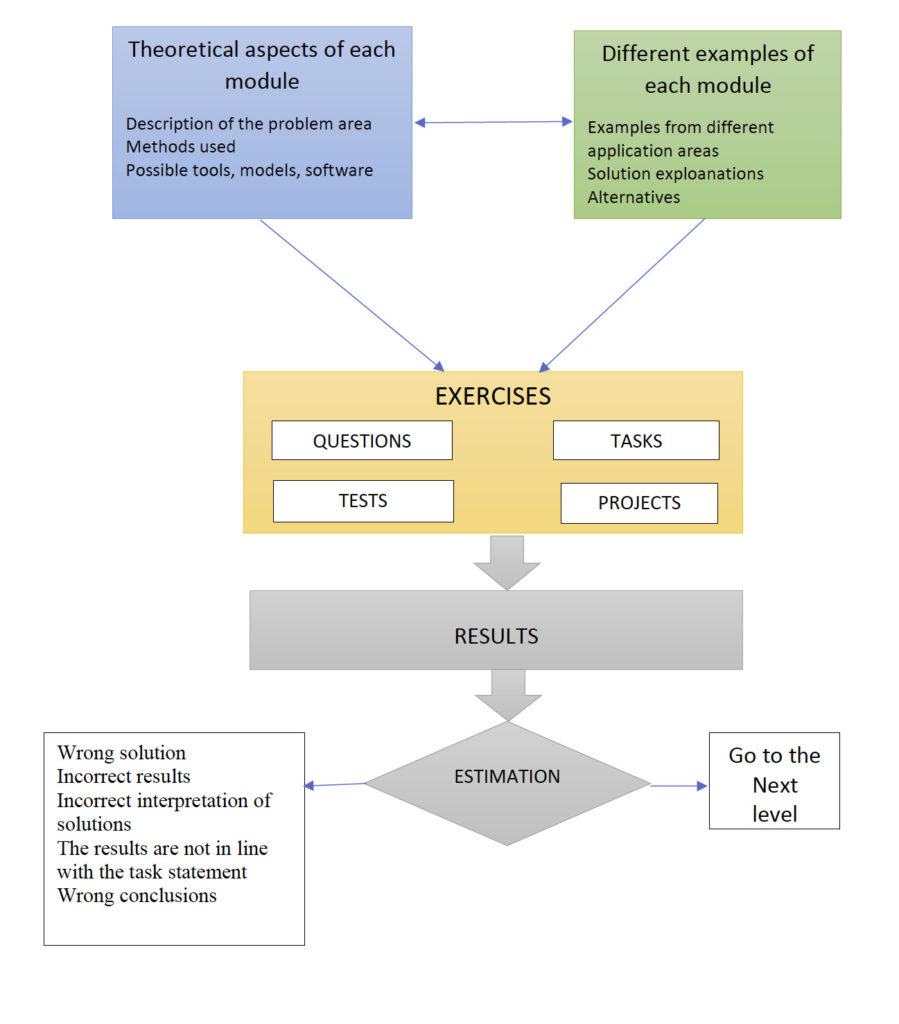

Task solving process